Your expensive machinery, equipment and molds can be well maintained and preserved by applying non-stick PTFE coats. Subsequently production increases and maintenance needs drop. We work with textile, food, pharmaceutical, surgical, sports and automotive industries.

Shahvar Industrial Coating has been a recognized name in P.T.F.E./Non-Stick Coatings since 1980 when our founder, Mr. Shahvar, introduced this type of coating in Pakistan. Later we started manufacturing non-stick cookware and household products, when we were licensed coaters of iron plates and sandwich makers for M/s. Philips Electrical Co. of Pakistan Ltd., with Teflon(TM) manufactured by M/s E.I. DuPont de numerous USA. We provide the best quality of product and services for our partners in the industry while maintaining competitive pricing.

We provide PTFE Coating services for the following products

- Textile sizing rolls / cylinders

- Textile dyeing & printing cylinders

- Textile guide & finishing rolls / cylinders

- Textile denim & finishing cylinders

- Textile cylinders for chemical treatments of denim clothes

- Rotary screw compressor rotors

- Heating plates of blister packaging machines

- Moulds & dies for easy release of products

- Electric irons & grills

- Confectionery and chocolate moulds

- Cake & Pizza baking trays

- Iron plates, nut bolts & washer coating

- Easy release of moulds, dies and rollers for rubber industry

- Easy release of rubber and eva form moulds, dies and rollers for surgical gloves, tyre, shoes and slipper industry

- Cutting blades of textile yarn for textile industry

- heat sealing & cutting blades & bars for textile and packaging industry

- Any metals requiring non-stick / chemical resistance and properties of PTFE.

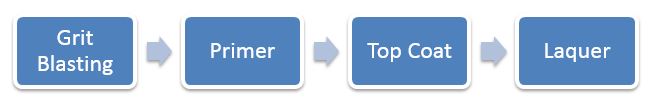

We also provide additional pre-treatment services of ‘rust conversion’ before the P.T.F.E. coating process. This restores the mechanical properties of metals that have already been corroded. Then the P.T.F.E. coating prevents it from further rusting.